Surface Grinding Machine Pdf

Lock the dresser onto the bed by turning the magnetic chuck on. Surface grinding machines ( for flat or formed profiles) cylindrical grinding machines

14 Types Of Grinding Machines Working Diagram Pdf

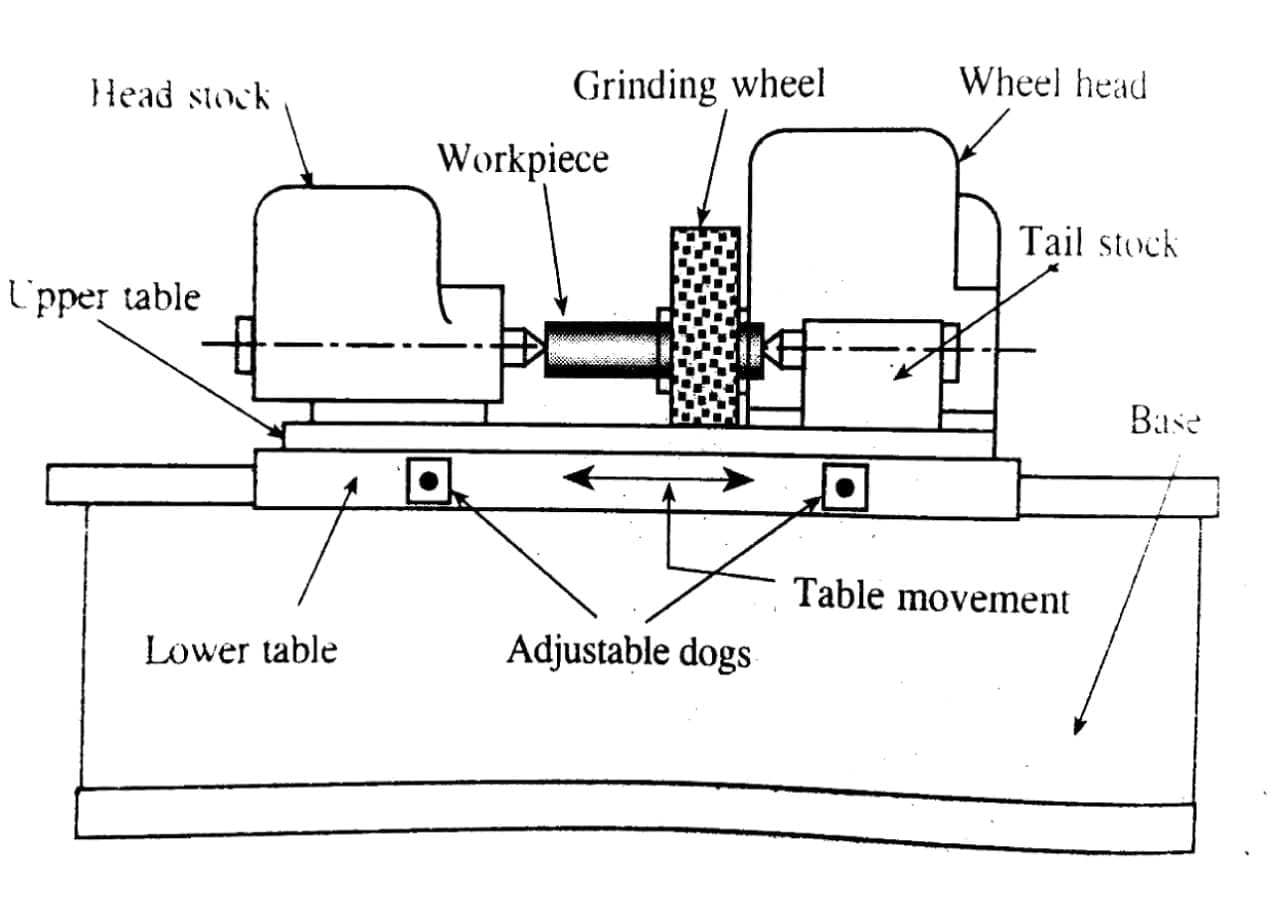

The workpiece is supported on a rectangular table which moves back and forth and reciprocates beneath the grinding wheel.

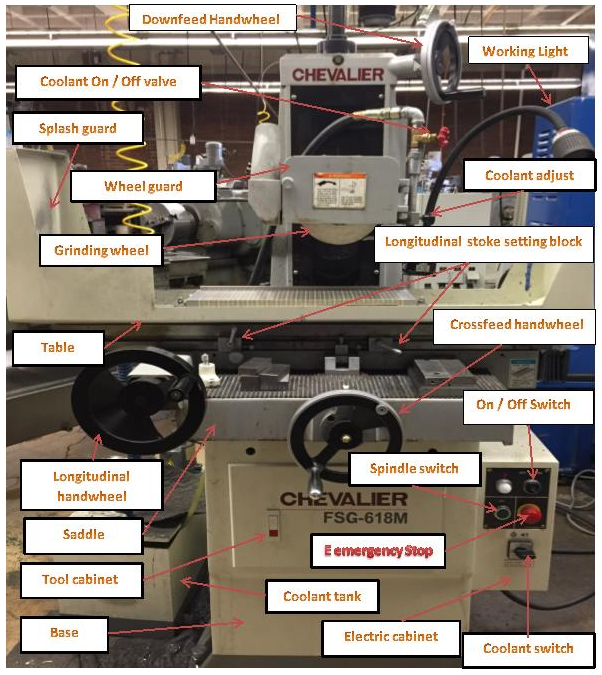

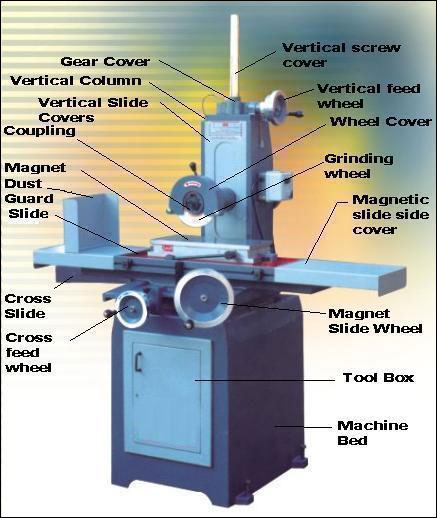

Surface grinding machine pdf. A surface grinding machine is used for grinding flat surfaces. The tool is hand held and moved across the face of the wheel continually to avoid excessive grinding in one spot. A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the unwanted material to get the desired surface finish, correct size, and accurate shape of the workpiece.

Definition, diagram, parts, working, advantages, disadvantages, and applications [pdf] drilling machine is used to make circular holes on the components with the help of drill bits. Surfaces may be straight, tapered, steps or profiled. Universal cylindrical surface grinder 3.

It is generally used to finish bores of cylinders of ic The abrasive belt grinding can reduce. For cylindrical, internal, centreless and surface grinding operations.

All the parameters depend on the clays of work for which the wheel is used, size and power of grinding machine using the wheel. For sharpening miscellananeus cutters a universal type grinder is used. It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece.

Work piece is secured on a chuck attached to A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial. Grinding machine to achieve good tolerance as well as better surface finish for various materials such a s metal, glass, ceramic, rock and specified material.

This machine may be similar to a milling machine used mainly to grind flat surface. Place the diamond wheel dresser onto the bed. • the typical precision of a surface grinder depends on the type and usage, however.

Plain centre type cylindrical grinder 2. Cylindrical surfaces by removing a small amount of material. • the grinding wheel rotates at 3600 rpm, has a diameter (d) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2.

Table travel mm 480 510 510 max. Size of grinding wheel (dia x width x bore) 200 x 13 x 31.75 (mm) model. Surface grindingis used to produce a smooth finish on flatsurfaces.

For better surface finishing better accuracy or close tolerances for hardened materials very little metal removal cutters: In the last article, we had discussed the drilling machine, surface grinding machine, milling machine, lathe machine, etc. Between center or centreless and method of operation i.e.

In this article, we will learn about the working principle and operation of surface grinding machine. The surface grinding machine is used for grinding flat surfaces. Known for its quality, durability and corrosion resistance.

Surface grinding machine kgs 150, kgs 250, kgs818ah/ahr/ahd *picture shown with optional accessories parameters unit kgs 150 kgs 250 kgs818ah/ahr/ahd working surface of table mm 150 x 450 200 x 460 200 x 460 max. The motor has a power of 2 kw. Types of surface grinding machines tool and cutter grinder in grinding tools by hand a bench or pedastal type of grinder is used.

• the work piece moves (v) at 1.5 m/min. These mini surface grinder machines can. The chip thickness ratio (r) is 10.

(a) surface grinding machine (b) cylindrical grinding machine (c) internal grinding machine (d) tool and cutter grinding machine 29.1 surface grinding machine: Grinding ± 0.008 5 to 75 lapping ± 0.005 2 to 15 honing ± 0.005 4 to 30 super finishing ± 0.003 1 to 10 different surface finishing processes are described below. Internal grinding is not expensive and provides a high degree of surface finish.

Cylindrical grinding machine this machine is used to produce external cylindrical surface. Broadly there are three different types of cylindrical grinding machine as follows: These wheels vary in size, diameter and width of the face.

Internal grinding machines are classified according to the method of holding work, i.e. Cross travel mm 178 250 250 distance between table surface and spindle center mm 360 530 530 max. The cylindrical workpiece is rotated between centers to provide a surface speed of generally 18 to 30 m/min, and the grinding wheel rotating generally at 1200 to 2000 m/min, is engaged to perform.

Equipment for surface grinding machine • surface grinder with electromagnetic chuck, inset shows a manual magnetic chuck • a surface grinder is a machine tool used to provide precision ground surfaces, either to a critical size or for the surface finish. Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimension. Honing honing is a surface finishing operation based on abrasive action performed by a set of bonded abrasive sticks.

Keep the diamond dresser ¼ of an inch to the left of the center of the wheel. The main components of an internal grinding machine are the work head and wheel head. Cylindrical grinders, internal grinders, and surface grinders, the spindle precision of the machine tool grinding wheel, the accuracy and stability of the feed system, the rigidity and vibration resistance of the whole machine tool are closely related to the surface roughness.

However, some types of surface grinders are also capable of producing contour Whereas, in today's article, we… 3.2.2 geometric accuracy of the grinding machine.

The surface grinding machine is classified as follows. Grinding is a nishing process used to improve surface nish, abrade hard materials, and tighten the tolerance on at and. Reciprocating surface grinding machines generally have horizontal wheel spindles and mount straight

Grinding Machine - Parts And Functions - Mechanical Walkins

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

Chapter 5 Surface Grinder Manufacturing Processes 4-5

Hydraulic Surface Grinding Machine - Surface Grinding Machine Manufacturing In India

Guru Arjan Machine Tools Surface Grinder Machine Surface Grinding Machine Surface Grinding Machine Manufacturer

Surface Grinder Pdf Grinding Abrasive Cutting Metalworking

Une Maison Confortable Pour Vous Parts Of Surface Grinding Machine Pdf

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

Types Of Grinding Machine Parts Working Principle Grinding Wheel - Engineering Learn

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Manual Surface Grinder - Wheel Head Moving Surface Grinders Manufacturer From Faridabad

Muhammad Musa Muslimmuhammad313 - Profile Pinterest

Hmt Surface Grinding Machine Max Grinding Length 6 Mtr Grinding Wheel Size 1500 Mm X 300 Mm Id 21749637588

Hydraulic Circuit For Surface Grinding Machine Explained In Details - Engineering Arena Projects Seminar Topic Gate Tutorials Engineering Articles

Grinding Machine Definition Parts Working Principle Operation Advantages Application Notes Pdf

14 Types Of Grinding Machines Working Diagram Pdf

14 Types Of Grinding Machines Working Diagram Pdf

Grinders - Kent Industrial Usa