Wire Edm Machine Working Principle

Electrical discharge machining (edm) is a process of removing material by exposing it to reoccurring controlled electric discharge. Wire electrical discharge machining (wedm) is an advanced thermal machining process capable of accurately machining parts with complicated shapes, especially for the parts that are very difficult to be machined by traditional machining processes.

Principle Of Electric Discharge Machining Download Scientific Diagram

Cnc wire cut ~ cnc wire edm ~ wire edm ~ wire edm machine working principle.

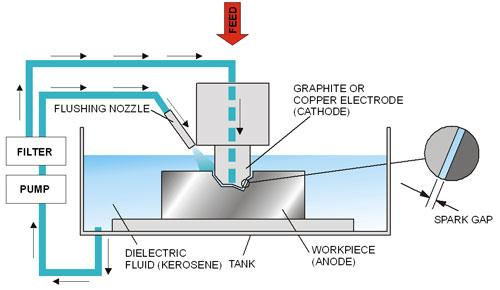

Wire edm machine working principle. Cnc wire cut edm machine puts impulse voltage between electrode wire and workpiece through impulse source, controlled by servo system, to get a certain gap, and realize impulse discharging in the. The dielectric liquid, in this case, is usually deionized water. Wedm process is based on the conventional edm sparking phenomenon utilizing the widely accepted.

It is often used for the production of metal parts with complex geometry. Here, the thin wire acts as the electrode. As the electric discharge takes place between an electrode/wire and workpiece, the thermal energy is generated on a workpiece.

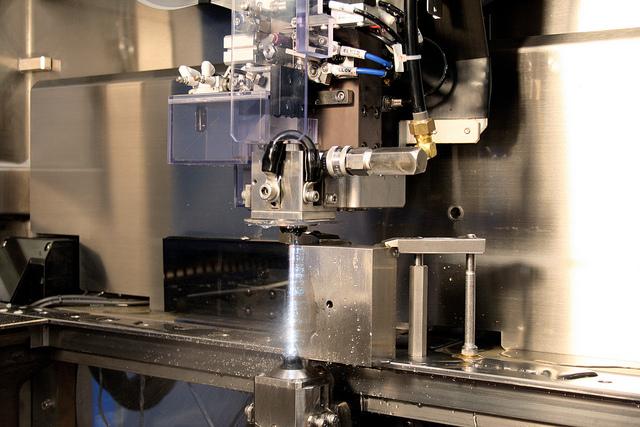

Electrical discharge machining process works on the basic principle of spark generation and metal removed by spark erosion. The wire is threaded through the hole to start. Your wire edm machine uses a thin electrically conductive wire (generally brass) as an electrode to cut the workpiece to create the desired profile or shape.

Working principle in edm, the tool electrode and the workpiece are connected to the two poles of the pulse power supply respectively, and immersed in the working fluid or charged into the discharge gap. Edm spark erosion is same as electric spark which burn a small hole in a piece of metal through witch it contacts. During the wire edm, there is the continuous unfurling of the wire from an automated feed using a spool.

Electrical discharge machining (edm) is a process of removing material by exposing it to repetitive controlled electrical discharges. As shown in figure, at the beginning of edm operation, a high voltage is applied across the narrow gap between the electrode and the workpiece. A water jet or air jet guides the wire through the work piece.

When a discharge occurs between the electrode/wire and the workpiece, heat energy is generated on the workpiece. It is suitable for thermoelectric phenomena. On the machining area, each discharge creates a crater in the workpiece and an impact on the tool.

The machine automatically makes the necessary mechanical and electrical connections. This can be done with a conventional drill or with an edm drilling machine. The wire edm process is a subtractive manufacturing process.

Principle of wire cut edm. Edm cutting is always through the entire workpiece. Sometimes referred to as wire erosion or spark edm, wire edm is a popular process.

Modern wire edm machines provide automatic threading. This high voltage induces an electric field in the insulating dielectric that is. The spark generated by this process produces heat, which remove metal by erosion and evaporation.

To start wire machining it is first necessary to drill a hole in the workpiece or start from the edge. It involves the use of a brass wire or thin copper to cut the workpiece.

Wire Edm Guide To Edm Wirecut Machine Process Uses - Fine Metalworking

Pdf Review Of Wire-cut Edm Process On Titanium Alloy Semantic Scholar

How Does Wire Cutting Work Dienamics

Working Principle Of Wedm Download Scientific Diagram

Working Principle Of Edm Download Scientific Diagram

Mechanical Engineering Electrical Discharge Machining Edm Principles

Principle Of Wire Cut Edm1 Download Scientific Diagram

Principle Of Wire Cut Edm - Kingred Electrical And Mechanical Technology Co Ltd

Principle Of Wire Cut Edm1 Download Scientific Diagram

Production Technology Of Agril Machinery Lesson 7 Electrical Discharge Machining Edm

Wire Cut Edm Machine - Kingred Electrical And Mechanical Technology Co Ltd

How Does Wire Edm Work

Wire Cut Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram - Youtube

What Is Electrical Discharge Machining Edm Process And How It Works - Mechanical Booster

Electrical Discharge Machining How Edm Machine Works

Mechanical Engineering Electrical Discharge Machining Edm Principles

Wire Cut Edm

Electrical Discharge Sawing Machineeds Is The Best Solution For The Special Steel Alloys Cutting - Tech Edm Trade Co Ltd

Principle Of Wire Cut Edm - Kingred Electrical And Mechanical Technology Co Ltd